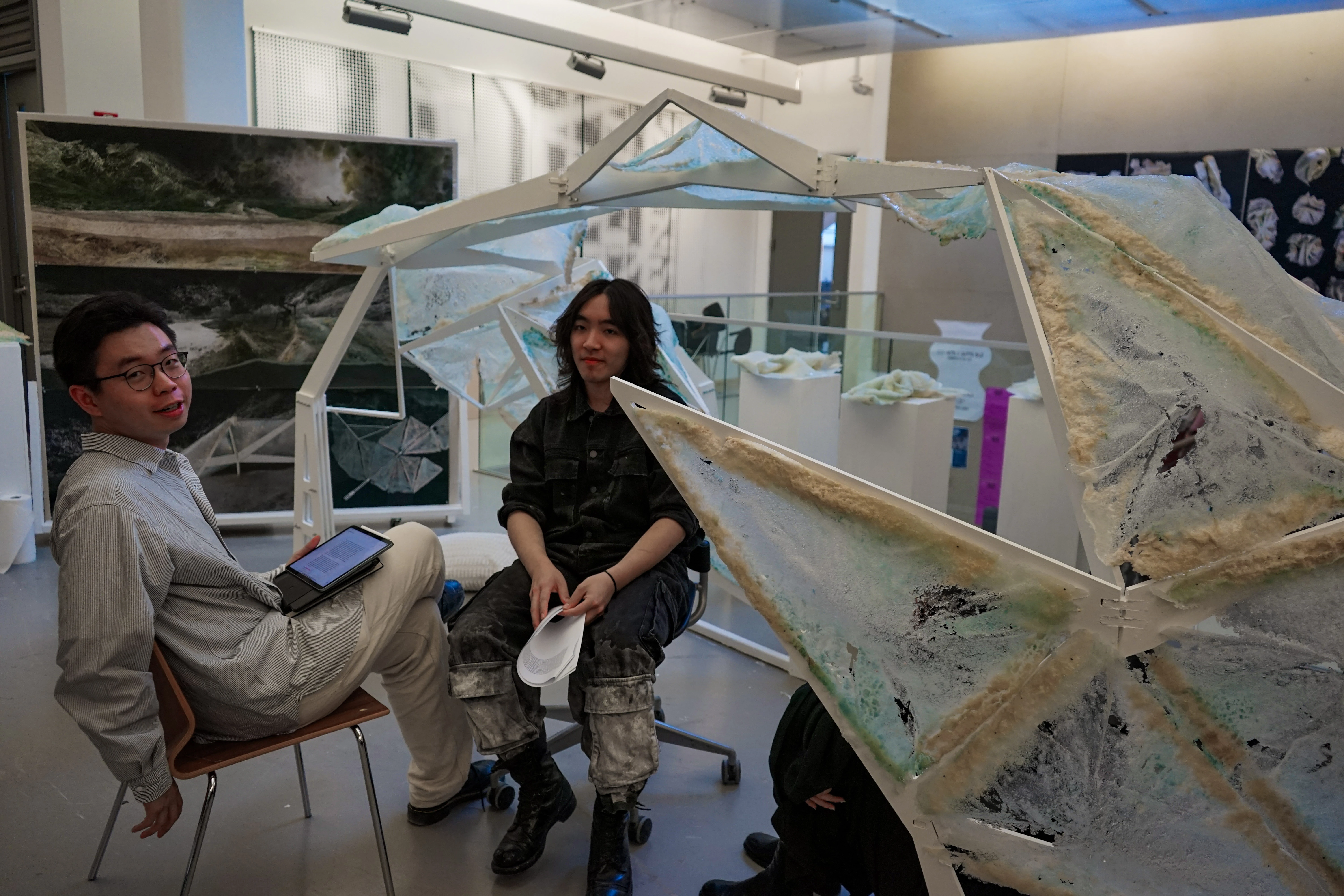

THESIS fabricated bio-encapsulation

Designed in collaboration with Crystal Giard

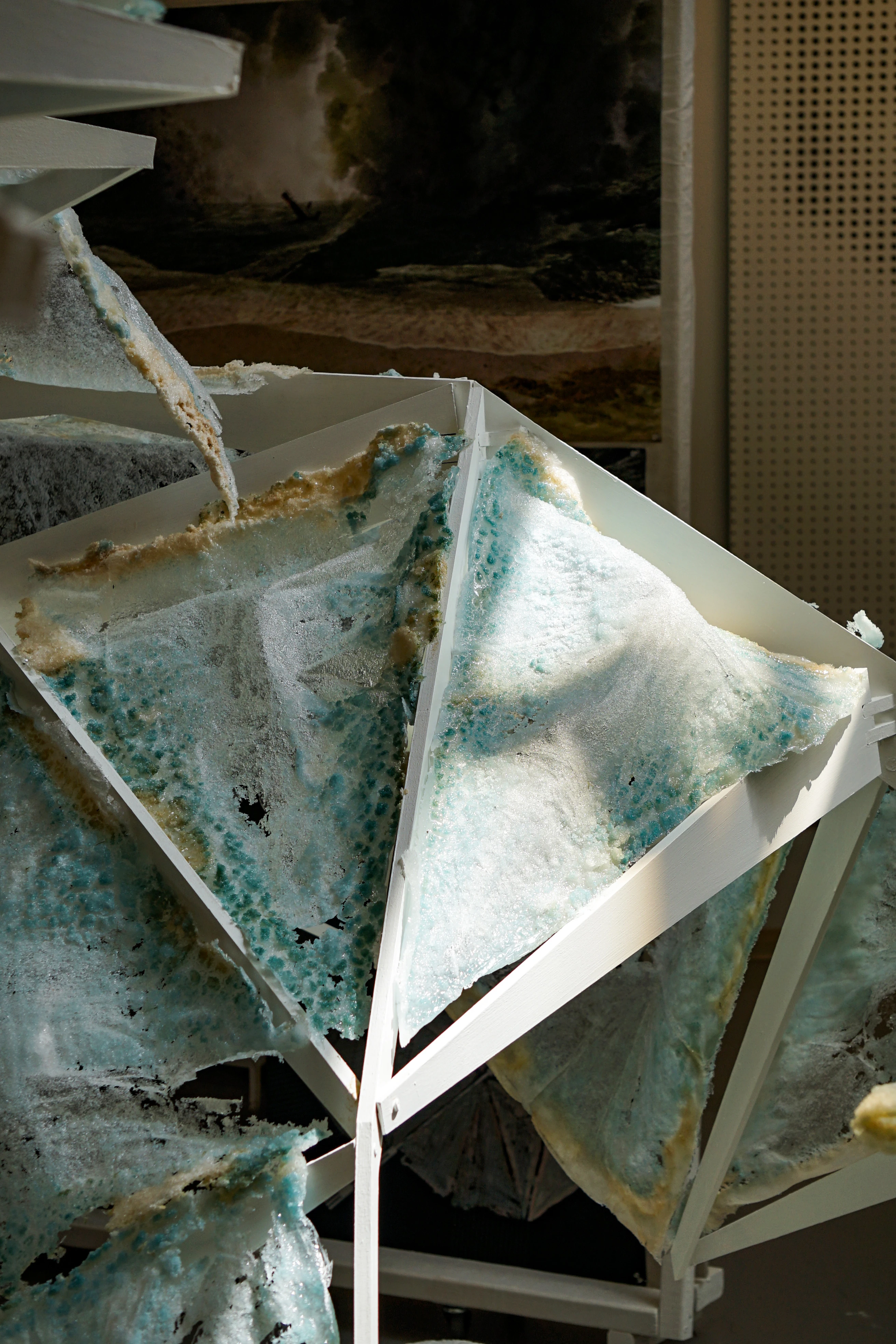

Harmful Algae Blooms, and the proliferation of these toxic organisms due to industrial runoff, occupy the core of our project. As we look to the future of design, we propose that in order to navigate ecological degradation, we must assert a unique design language into existing toxic algae. Our design research proposal establishes a cyclical rhetoric enmeshed in the natural cycle of industrial production, runoff, and algae growth. We are responding to this cycle intentionally, using a custom designed 3D printer to engage algae at the points of greatest exponential growth. We are using this novel process of 3D printed fabrication of bio-material development that can be directly applied near agricultural runoff as an opportunity to stop toxic algae from entering waterways and create a new formal language for bio-encapsulation.

Global industrial agricultural practices are notorious for uncontrolled runoff in the form of nitrogen and phosphorus. These common fertilizer chemicals serve to support the growth of algae in oceans and lakes. Between 2003 and 2020 global algal blooms increased in size by 1.5 million square miles and became 60% more frequent. Our project acknowledges that this cycle would be impossible to stop completely. Instead, we intend to appropriate these toxic organisms into an opportunity to develop a new material.

The agriculture industry has tried to reduce runoff through the use of a hydrogel called sodium polyacrylate. When combined with liquid, this dry powder will absorb and expand to hundreds of times its original volume, creating a gel. Our 3D printer makes use of existing sodium polyacrylate and existing toxic algae; when combined together, they retain a predetermined form. The intervention we have designed consists of an 8ftx8ft 3D printer. We assigned three-dimensional form and depth to our surfaces using a process of sand molding, inspired by other academics working with robotics, similar to the work of Gramazio Kohler. Our machine uses a base layer of sodium polyacrylate and “prints'' a constant flow of liquid algae culture on top of the base layer. The flow of algae is controlled by a peristaltic pump set at 120ml/min, which produces a gel within 3-5 seconds of contact. Within 24 hours a solid surface is created, holding its form after 72 hours. Once dried, the once liquid algae becomes a unique solid form.

Acknowledging the vast quantity of both algae and sodium polyacrylate at these coastal runoff locations allows us to predict a systematized approach to ecological engagement: large units created from already growing algae, merging together as the system grows and expands. By creating a form which is intrinsically linked to the substance it is made from, we can create productive responses to ecological degradation and manufactured symbiosis. Our project currently operates at a 1:1 scale, however the system, chemical combinations, and logic of manufacturing can be scaled up . We envision the possibility of an entire ocean ecology, hampered by harmful algae blooms, becoming a site for this intervention. As algae continues to exponentially grow, the system we have created will serve as a register of the true harm that industrial pollution forces on our ecosystem. This endeavor records the direct impact of runoff pollution while using innate physical form to create a new cycle of pollution and growth: one where design is not a solution to the toxicity of our world, rather an opportunity to encapsulate toxic algae ,resulting in a new formal language for bio-encapsulation.